Taking CNC to the next level of accuracy

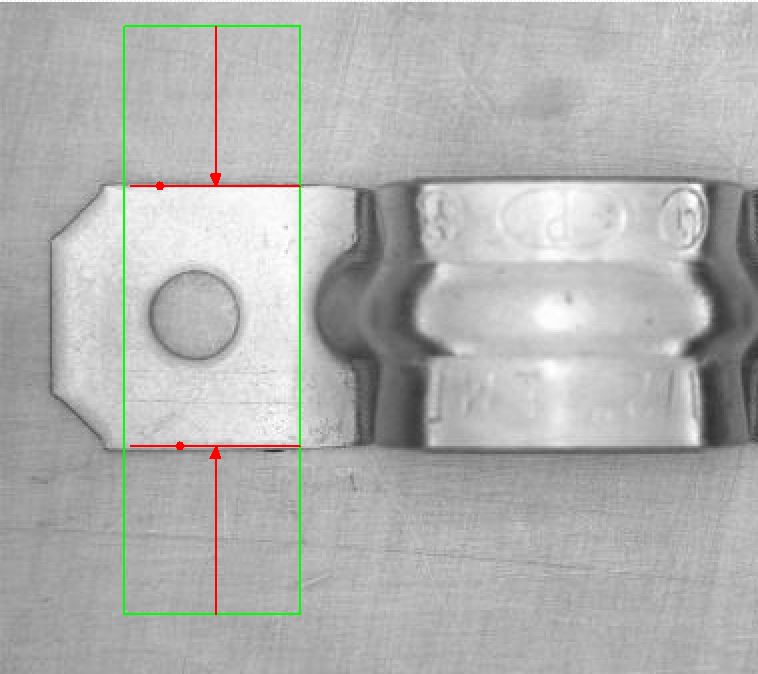

Machine Vision confers ‘sight’ on machines to make them more intelligent. In a manufacturing context, this can be used to vastly improve key process functions through metrology, improving overall accuracy and ensuring final product quality. Performance and flexibility of CNC machines can be enhanced by the addition of Machine Vision, or other suitable forms of optical metrology.

This upgrades them to guided CNC machines which have the benefits of in-process inspection, measurement and control, allowing for dynamic alignment and ‘live’ metrology that can dramatically improve yields.

Viska Systems offer the perfect combination of skills to help you apply this technology, pairing our major expertise in high-accuracy optical metrology with significant experience in CNC system design.

For laser cutting of micro-tubes and stents, or any specialised Machine Vision guided CNC application – contact Viska Systems now or Click Here to learn more.