Discover how our customer enhanced their competitiveness and reduced inspection time from 30 minutes to just 3 minutes.

Visable

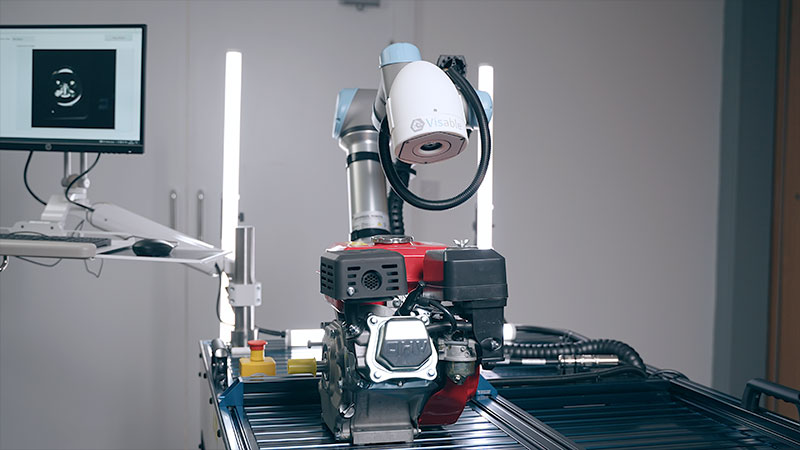

Robotic Vision Inspection Solution

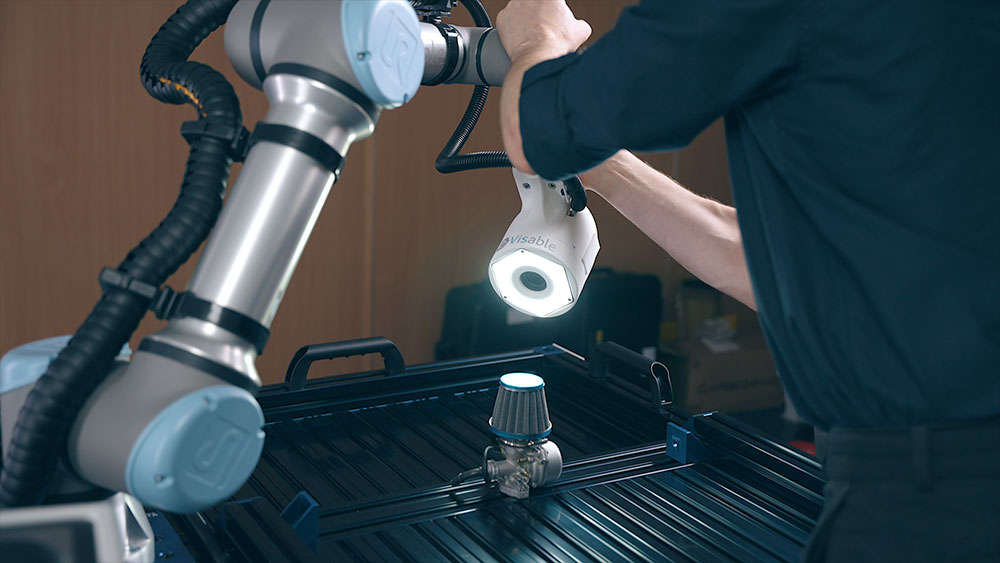

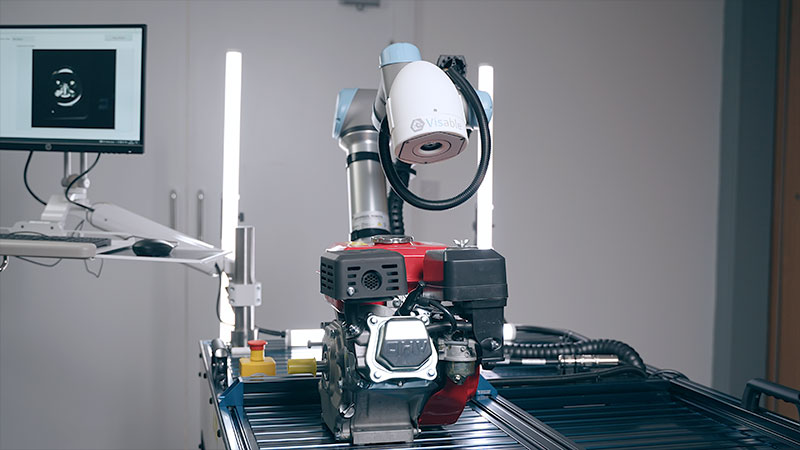

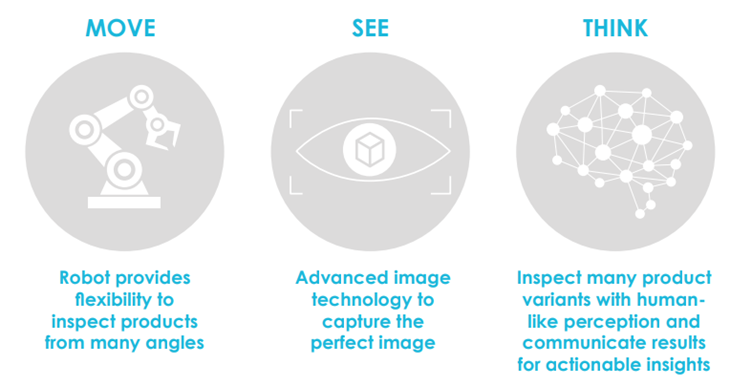

Visable is an advanced automated inspection system which incorporates the latest Machine Vision, Robotics, and AI technologies to perform automated vision inspection tasks.

It seamlessly combines industrial robots with image processing tools and operates them as a unified system, with human level perception.

Visable streamlines your inspection process by automating complex visual quality inspections, reducing the time spent on manual inspections. This not only increases efficiency but also minimizes the risk of human error, ensuring faster and more reliable outcomes.

Eliminate inspection errors, improve quality control and achieve significant cost reductions with Visable.

Visable is your one-stop shop for Robotic Inspection

Discover Visable

Why choose Visable?

Key features

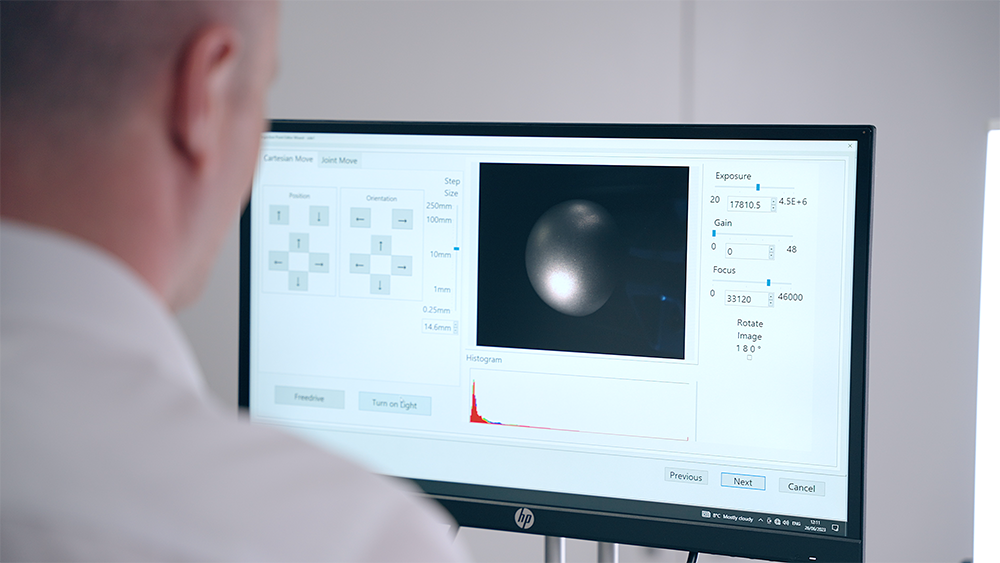

NO-CODE, USER-FRIENDLY INTERFACE

Visable combines Robotic Control, Vision Inspection, Data Collection and Factory Communication stages into a simple and easy to use software application.

Its intuitive, user-friendly interface makes it easy for any team member to operate, eliminating the need for extensive training or specialized knowledge.

ADVANCED VISION AND DEEP LEARNING

Visable incorporates cutting-edge vision and deep learning technologies, making it possible to detect even the smallest and most elusive defects. This ensures higher accuracy and precision in your inspection processes, improving overall product quality.

Visable incorporates cutting-edge vision and deep learning technologies, making it possible to detect even the smallest and most elusive defects. This ensures higher accuracy and precision in your inspection processes, improving overall product quality.

INDUSTRY 4.0/IIOT COMPATIBLE

Visable is fully compatible with Industry 4.0 and IIoT (Industrial Internet of Things), allowing seamless integration with other smart factory devices. This connectivity enables you to create a more connected, automated, and intelligent production environment.

Visable is fully compatible with Industry 4.0 and IIoT (Industrial Internet of Things), allowing seamless integration with other smart factory devices. This connectivity enables you to create a more connected, automated, and intelligent production environment.

SEARCHABLE DATA INSIGHTS

With Visable, you can track and analyse inspection performance through easily searchable data insights. This feature provides valuable information for making informed decisions, helping you optimize your production processes and improve overall efficiency.

With Visable, you can track and analyse inspection performance through easily searchable data insights. This feature provides valuable information for making informed decisions, helping you optimize your production processes and improve overall efficiency.

REDUCED COSTS & INCREASED QUALITY CONTROL

By eliminating manual inspection errors and reducing the time spent on quality checks, Visable drives significant cost savings while enhancing quality control. It enables businesses to maintain high standards of production with less effort and reduced operational costs.

By eliminating manual inspection errors and reducing the time spent on quality checks, Visable drives significant cost savings while enhancing quality control. It enables businesses to maintain high standards of production with less effort and reduced operational costs.

Applications

See how our customer eliminated inefficiencies and minimized the risk of errors in their inspection process, even across a diverse range of parts.

Technical specifications

DIMENSIONS | 300 (W) x 300 (D) x 500 (H) |

WEIGHT | 100kg |

CYCLE TIME (excluding load / unload time) | 1 sec / inspected item |

FLOORSPACE REQUIREMENTS | 1.6 m (W) x 1 m (D) x 2 m (H) |

SAFETY GUARDING | Rear side placed against wall, 3 sides guarded with light curtain safety system. |

FLOOR ANCHORING | Braked wheels. System is provided with wheels attached for mobility. |

POWER REQUIREMENTS (per system) | 220V single phase. Target voltage 200–230 (+/- 10%), 50/60 Hz, 13A full load current. |

Visable Tutorials

Playlist

0:16

0:16

0:16

0:16

0:16

0:16

0:16

0:16

0:16

0:16

0:16