Machine Vision Factory Integration

Home » Expertise » Machine Vision Integration » Machine Vision Factory Integration

Home » Expertise » Machine Vision Integration » Machine Vision Factory Integration

So, your camera hardware is installed, your optics and lighting systems are optimized, your image processing techniques are programmed – but you are still not ready to launch on your manufacturing line!

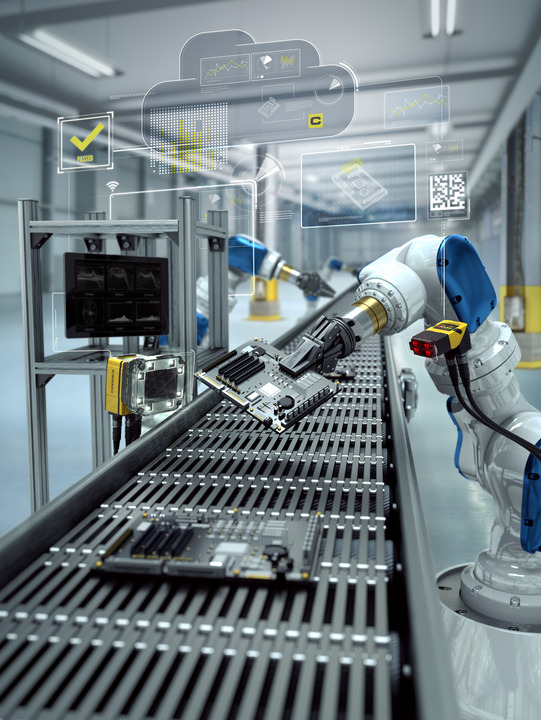

While the performance of the individual vision systems on a manufacturing line depend on their hardware and software setup individually, a successful project comes together only when all the systems work together in harmony. Practical considerations, such as product changeover, algorithm maintenance, operational efficiency, root cause analysis, and user access control – these are all the items which need to be implemented properly for an overall system to yield the optimal return on investment for the customer. This can only be achieved with the correct factory integration of the machine vision systems.

At Viska Systems, we have significant experience in the deployment of multiple camera installations on manufacturing lines and in the integration of these lines with Industry 4.0 factory technologies. Working in a variety of industries from food and beverage, to medical device, we understand the regulatory requirements within each sector and can deliver bespoke software/hardware solutions to optimize the manufacturing efficiency of the line.

Systems that we have developed offer features such as:

- User Access Control via Active Directory

- Instant update of all camera recipes for job changeover

- Error handling of hardware connections

- Output of system performance for line OEE analysis

So, if you have an application that could benefit from next level factory integration contact Viska Systems today to find out how we can bring your factory to the forefront of Industry 4.0.