Accurate counting is crucial for maintaining precision in manufacturing, but manual counting methods often lead to errors, inefficiencies, and production delays—especially when dealing with large quantities of parts. Whether it’s counting components, products, or materials, errors in this process can lead to costly shortages, surplus, or misallocations.

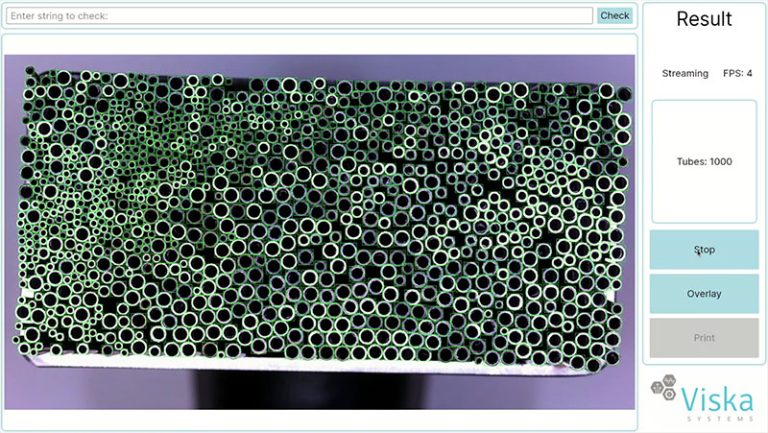

Viska Systems provides a cutting-edge counting solution that eliminates these challenges with advanced machine vision technology. Our system utilizes deep learning algorithms to count large numbers of parts or objects in real-time, offering operators instant feedback on the count. With the ability to process thousands of parts in a fraction of a second and perform over 20 trillion calculations per second, our solution maintains exceptional accuracy without compromising operational speed.

Our customers, including leaders in the medical device industry, have seen dramatic improvements in both accuracy and productivity. With less than 0.03% error in counting small objects like tubes and the ability to count over 3,000 objects in under a second, Viska Systems’ counting technology not only reduces human error but also accelerates processes and boosts efficiency. Most clients achieve a return on investment in just three months, making it a vital tool for streamlining manufacturing operations.

Learn how one of our customers in medical device industry utilised our solution, Viskam, to enhance the speed and accuracy of their counting process. Read the story here.