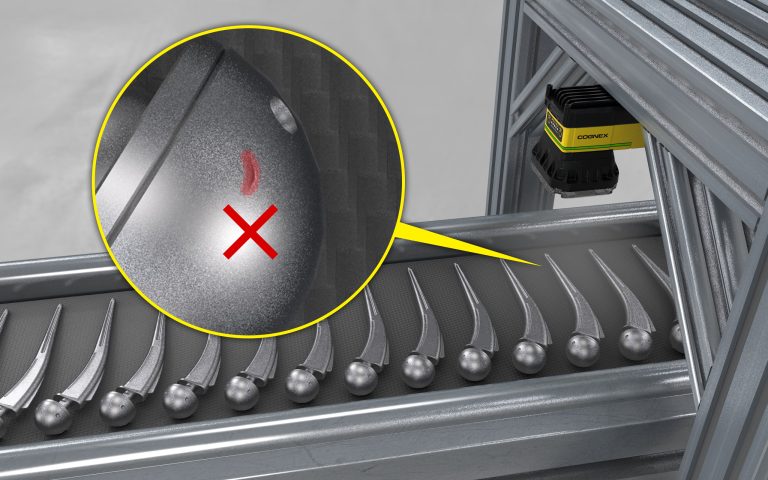

Detecting defects early in the manufacturing process is vital to maintaining high product quality and reducing waste, but it’s a task that many companies find challenging. Traditional inspection methods often rely on human inspectors, who may miss subtle defects such as surface scratches, dents, or assembly misalignments due to fatigue or the sheer volume of parts.

Viska Systems offers advanced defect detection solutions designed to eliminate these challenges. Our technology uses state-of-the-art vision systems and AI-powered software to automatically detect even the smallest defects, ensuring inspection accuracy at high speeds.

With our systems, manufacturers can reduce costly rework, scrap, and product recalls while improving overall production efficiency. Our defect detection solutions provide reliable, repeatable inspections, giving you the confidence that every product leaving your line meets the highest standards of quality.